Request a Quote

Heat Exchanger & HVAC Chiller Tube Sheet Repair

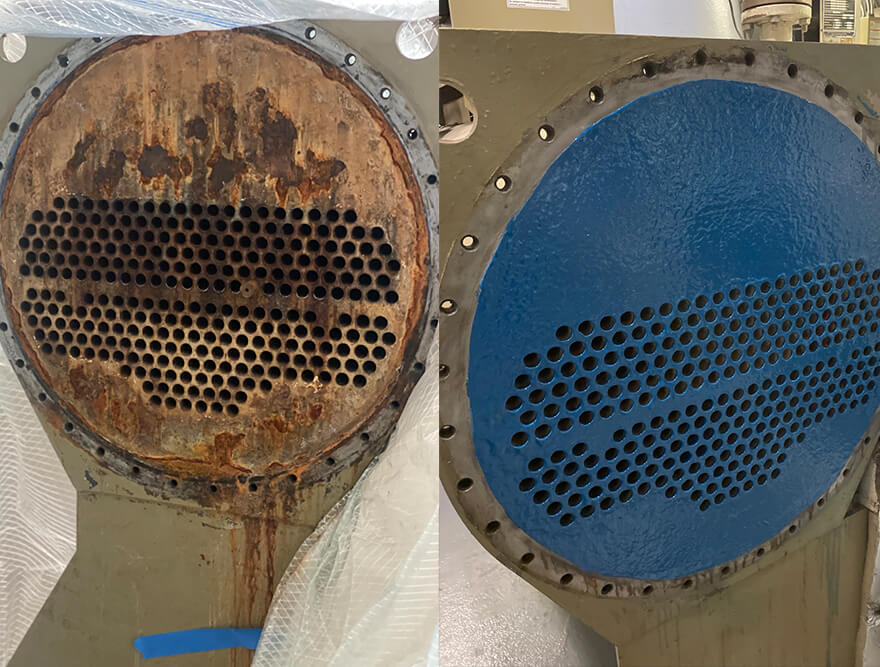

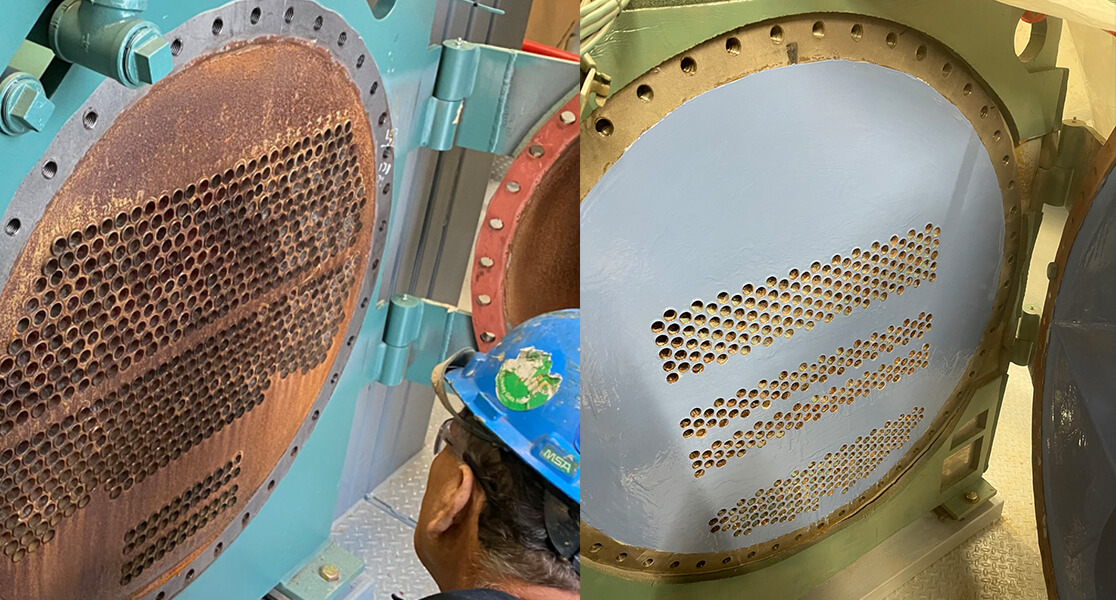

Fall maintenance may necessitate the chiller tube sheets repairs. Have you realized that your tube sheet has been harmed by galvanic corrosion? So, Take corrective action now rather than face the risk of potential leaks! Corrosion is primarily visible in the form of discoloration, staining, scale, and sometimes through holes in your chiller, boiler, and heat exchange components. In addition, blast cleaning can sometimes uncover previously undetected rust. Unfortunately, tube sheet failure leads to the most expensive and time-consuming chiller repairs.

Why choose us?

At NJ Reliable Coating LLC, our highly qualified and experienced technicians and engineers are committed to providing the highest quality and cost-effective heat exchanger & HVAC chiller tube sheet repair. Choose our experienced technicians and engineers for the following reasons –

- Highly qualified and certified LDAR contractors.

- Fast leak repairs without interrupting the day-to-day work of the facility.

- Use the highest quality repair materials.

- Durable and viable leak repair.

- State-of-the-art tools and advanced techniques.

So, don’t dismiss the warning signs of galvanic corrosion. Instead, contact us for a proactive heat exchanger & HVAC chiller tube sheet repair solution that saves both time and money.

Frequently Asked Questions

Heat exchanger & HVAC chiller tube sheet repair is a proactive service to correct corrosion and damage on tube sheets caused by galvanic corrosion. Our experts at NJ Reliable Coatings LLC evaluate corroded and stained tube sheets, rebuild and treat them to prevent leaks and costly failures. Our qualified technicians bring the components back to operation, protecting the chiller, boiler, and heat exchanger from corrosion and prolonging downtime, thereby ensuring seamless business operations.

Tube sheets need repair because of galvanic corrosion. It causes discoloration, staining, scale buildup, and sometimes holes in the metal. If these issues are ignored, they can lead to leaks and very costly chiller repairs. During blast cleaning, hidden corrosion and rust are often revealed, showing more serious damage. Timely tube-sheet repair from our expert team helps prevent further corrosion and expensive failures in heat exchangers and HVAC chiller systems.

The most visible indicators of sheet repair are the presence of corrosion in various forms, including discoloration and stains, the buildup of scales, and the complete exposure of rust. These may indicate galvanic corrosion and metal loss, posing a risk to the tube sheet’s integrity. Detection of these early warning signals helps prevent major repair work or breakdowns in the industrial heat-exchange units or chillers.

Our skilled technicians carefully assess damaged tube sheets and rebuild them using proven materials and methods. This process restores reliable operation and helps protect heat exchangers and HVAC chiller systems from future corrosion and leaks.

Yes, it can. Timely tube sheet repair prevents minor corrosion problems from turning into major leaks and equipment failures. Addressing corrosion on time and rebuilding damaged components with quality materials and techniques helps systems remain dependable and longer-lasting. The heat exchanger and chiller equipment are effectively secured through these proactive repairs, minimizing the potential for future downtime and expensive replacements.

The exact timing depends on the severity of corrosion and the extent of damage to the sheet. Commonly, it may take a few days to weeks, depending on the project’s size and the damage to the sheet. We, as a leading contractor, primarily focus on fast repairs to heat exchangers and HVAC chiller tube sheets. Our qualified team operates promptly, replaces damaged parts, and reduces downtime, using the latest tools and techniques without disrupting the facility’s operations.

Yes. Our LDAR-certified technicians perform fast tube sheet repairs designed to minimize disruption, allowing your facility to continue operating as smoothly as possible while we complete the necessary work.

Tube sheet repair services are essential wherever heat exchangers and HVAC chillers are critical to facility operations. These services help industrial, commercial, and municipal facilities prevent corrosion, minimize downtime, and maintain reliable performance.

Choosing our service at NJ Reliable Coatings LLC ensures you’ve access to highly qualified, LDAR-certified technicians. Our professional team delivers cost-effective, dependable tube sheet repairs using high-quality materials, best-in-class tools, and advanced techniques. We offer quick, advanced, and durable leak repair solutions without disrupting facility operations. So, we help businesses save time and money while protecting their valuable equipment from future corrosion and failure.

Services

Coating Contractors & Industrial Tank Lining Services in New Jersey

Similar To Coatings, Linings are designed to protect the internal surface of a tank, vessel, tower, or other internal surface of a structure. Internal surfaces used for immersion

Learn More

Leak Repair Service Contractors & Leak Detection Contractors NJ

Has your facility ever had to shut down to repair a leak? Has down time to repair a leak ever caused significant financial loss? Have you ever inspected an area at your facility

Learn More

Industrial Floor Painting

Industrial Floor Painting: Enhance Durability and Safety At Your Workplace It is especially important to maintain the quality of the floor in industrial applications. When selecting flooring for a warehouse, factory, or any extremely bodily-used area, the surface must be able to withstand loads of traffic, exposure to acids or chemical splashes, and other associated… Continue reading Industrial Floor Painting

Learn More

Industrial Spray Painting & Coating Contractors NJ

Protective coatings are applied on to surfaces/substrates and act as a barrier to inhibit or prevent corrosion. Each Coating is converted into a solid protective, decorative, or functional

Learn More

QA/QC & Third Party Coating Inspection Services NJ

QA/QC Inspection Services With Certified NACE CIP Level 3 Coatings Inspector on staff, Reliable Coatings ensures the highest standards of quality of their work and also offers

Learn More

Industrial & Secondary Concrete And Containment Repair Services NJ

Protect facility equipment and prevent chemical spills to safeguard the environment by using our repair service to restore and protect secondary containment areas. Thes

Learn More

Industrial Surface Preparation & Cleaning Services NJ

Surface Preparation is the method or combination of methods used to clean a surface of a substrate, remove loose and weak materials and contaminants from the surface, repair the surface, and roughen the surface to promote adhesion of a protective coating or lining system.

Learn More

Commercial Pool Painting Service in New Jersey

Expert Solutions for Pool Surface Coatings Maintaining the aesthetic appeal and hygiene of your swimming pool requires ongoing care. In addition to regular water chemistry checks, it’s vital for pool owners and managers to pay attention to the paint coating, as it plays a crucial role in the pool’s durability. Applying a new coat of… Continue reading Commercial Pool Painting Service in New Jersey

Learn More

Thermal spray metalizing | thermal coating & suppliers in NJ

Looking for a protective coatings that can last you up to 50 years? Metalizing or Thermal Spraying might be the solution. Enquire for More Details

Learn More

Heat Exchanger & HVAC Chiller Tube Sheet Repair

Heat Exchanger & HVAC Chiller Tube Sheet Repair Fall maintenance may necessitate the chiller tube sheets repairs. Have you realized that your tube sheet has been harmed by galvanic corrosion? So, Take corrective action now rather than face the risk of potential leaks! Corrosion is primarily visible in the form of discoloration, staining, scale, and… Continue reading Heat Exchanger & HVAC Chiller Tube Sheet Repair

Learn More

Sandblasting

What Is Industrial Sandblasting — and Why It Matters Industrial sandblasting is the process of using high-pressure abrasive materials to clean, strip, or prepare a surface — typically metal or concrete — by removing rust, mill scale, paint, and other contaminants. It’s one of the most critical steps in protecting and extending the life of… Continue reading Sandblasting

Learn MoreClient Reviews

Due to the quality & timeliness of their work, as well as highly professional communication and response time, NJ Reliable Coatings has established themselves as a trusted local partner of ours for work involving surface preparation, coatings, lining, and abrasive blasting. Dan and his team are committed to doing things the right way and ensuring the success of their customers. If you are in need of a no hassle, no stress contractor to get the job done, look no further than NJRC.

Ian May Regional Manager- Sponge Jet Inc

Great company to work with! Always looking into new technologies to add value to their clients assets and consistently staying on top of timelines and finishing work to the specification. Would recommend NJ Reliable Coatings for all your coating projects.

Armorica Sales Inc

Due to the quality & timeliness of their work, as well as highly professional communication and response time, NJ Reliable Coatings has established themselves as a trusted local partner of ours for work involving surface preparation, coatings, lining, and abrasive blasting. Dan and his team are committed to doing things the right way and ensuring the success of their customers. If you are in need of a no hassle, no stress contractor to get the job done, look no further than NJRC.

Ian May Regional Manager- Sponge Jet Inc

Great company to work with! Always looking into new technologies to add value to their clients assets and consistently staying on top of timelines and finishing work to the specification. Would recommend NJ Reliable Coatings for all your coating projects.

Armorica Sales Inc

Blog Posts

January 9, 2026

Why You Should Hire a Professional Leak Repair Company Before the Damage Gets Worse

A small leak might look harmless today, but give it time. Pressure changes, temperature shifts, aging materials, worn-out valves—these little factors can make things worse. And before you know it, what started as a minor issue becomes a full-blown problem...

Read More

November 26, 2025

Signs You Need an Industrial Painting Contractor: How to Choose the Right One

Keeping your industrial facility in good condition is vital for its longevity and safety. One of the most overlooked things in the context of maintenance is interior paint, which plays a very important role in the structures, equipment, protection of...

Read More

May 12, 2025

What is the Role of Sandblasting Contractors in New Jersey

Commercial sandblasting, also known as abrasive blasting, is an essential surface preparation procedure for restoration projects. The high-pressure sandblasting machines removes rust with old coatings, grime, and other forms of dirt using abrasive materials. Sandblasting Servicesare extensively used to prepare...

Read More