Request a Quote

QA/QC Inspection Services

Is your industrial facility in need of a QA/QC Coating Inspection?NJ Reliable Coatings LLC is a leading provider of surface coating and other paint services, and our Certified NACE CIP Level 3 Inspector on staff provides quality QA Coating Inspection Services in NJ. The process of coating inspection is intergal to any coating project in any facility. Quality Assurance (QA) and Quality Control (QC) are vital steps in ensuring that the painting specifications and contract documents are fulfilled. At NJ Reliable Coatings LLC, we take on each QC Coating Inspection Services in NJ as a chance to prove our deliverance of quality uncompromised. Our inspectors take all measurements to check that the painting specifications meet the standards of the specification and all quality systems. An audit function documenting the contractor’s control is one of the key stages in the surface preparation and coating application process. Daily and periodic visual observations, confirmatory testing, and duplicate spot checks of critical coatings inspection are conducted using QC documentation.

- Environmental Testing

- Dry Film Thickness-DFT Measurements

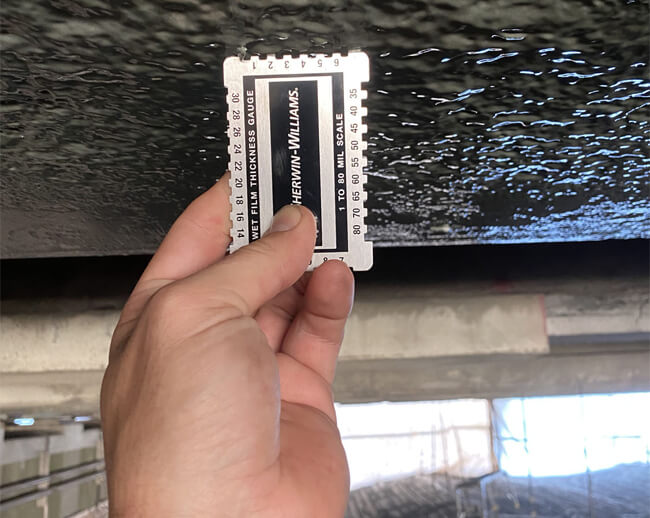

- Wet Film Thickness-WFM Measurements

- Holiday/Pinhole Detection

- Spark Testing

- Hardness Testing

- Failure Analysis

- Anchor Profile Testing

- Visual Cleanliness Inspection

No structure, pipe, or industry is insignificant when it comes to public safety. To keep them standing strong and last a good number of years, combine the highest quality services by hiring our skilled and extensively trained team of professionals for surface coatings and annual inspections without delay.

Why choose NJ Reliable Coatings LLC Inspection Services in NJ?

All our services are thoroughly planned and strategically executed by trained professionals. Each project begins with a review of the contractor’s coatings submittals to check conformance with the standard criteria of the painting specifications. Next, a facility-specific inspection plan is developed by a Certified NACE CIP Level 3 Inspector based on the owner’s facility-specific inspection needs.

- Checking that the contractor implements the agreed-upon programs throughout the construction and surface coating;

- Ensuring the QC processes meet the requirements of the set specifications;

- NJ Reliable Coatings LLC inspector follows through each step manually and stays on-site for the whole duration of the inspection;

- Verifying QC test results that are performed to specific standards;

- A detailed report is provided, documenting every crucial progress, observation, and results of the quality assurance measurements.

Frequently Asked Questions

QA/QC coating inspections are a set of systematic methods by which coatings/paints are validated to conform to their approved standard. The purpose of this process is to verify that surface preparation and application methods, as well as the final coating application, meet the contract specifications.

QA/QC Inspection plays a critical role in the application of industrial coatings, ensuring they are applied correctly in line with approved specifications. If QA/QC inspections are not performed correctly, they can lead to paintwork failures. This might result in corrosion or costly repairs, especially if it leads to structural shortcomings.

At NJ Reliable Coatings, we offer various inspection tests and measurements that ensure the coating quality. The different tests and measurements include:

- environmental testing

- dry film thickness

- wet film thickness measurement testing

- holiday or pinhole detection testing

- spark testing, hardness testing

- failure analysis

- anchor profile testing

- visual cleanliness inspection

Coating inspections are performed by experienced in-house inspectors, including a Certified NACE CIP Level 3 Inspector. Our inspectors conduct measurements, testing, evaluations, and documentation to ensure all coating work meets applicable standards and specifications.

Yes, the QA/QC inspection can be provided for third-party inspection. NJ Reliable Coatings LLC is also an independent coating inspection company with operations across New Jersey.

QA/QC coating inspections are beneficial for facilities and structures where surface protection, corrosion prevention, and public safety are critical. This includes industrial facilities, infrastructure components, tanks, pipelines, bridges, and public buildings that require long-term coating performance.

Inspection reporting is very detailed and comprehensive, and includes a complete record of the coating procedure. It consists of a complete project report detailing the progress and work on site, and the results of tests and measurements taken to ensure the coating process conforms to the specific standards.

Yes, inspection plans can be done on a project-to-project basis. A Certified NACE CIP Level 3 Inspector can provide a facility inspection plan tailored to the owner’s requirements, reflecting the unique circumstances.

Yes. Our inspectors follow the inspection process manually and remain on-site throughout the coating application to verify surface preparation, coating application, and compliance with approved specifications.

Quality Assurance (QA) is defect-preventative, ensuring the proper procedures are in place before the actual coating task to prevent defects. Quality Control (QC) is the process of detecting defects by inspecting and testing the applied coating. QA is process-driven, while QC is product-driven. Both are important for ensuring the coating job is done according to standards.

Services

Coating Contractors & Industrial Tank Lining Services in New Jersey

Similar To Coatings, Linings are designed to protect the internal surface of a tank, vessel, tower, or other internal surface of a structure. Internal surfaces used for immersion

Learn More

Leak Repair Service Contractors & Leak Detection Contractors NJ

Has your facility ever had to shut down to repair a leak? Has down time to repair a leak ever caused significant financial loss? Have you ever inspected an area at your facility

Learn More

Industrial Floor Painting

Industrial Floor Painting: Enhance Durability and Safety At Your Workplace It is especially important to maintain the quality of the floor in industrial applications. When selecting flooring for a warehouse, factory, or any extremely bodily-used area, the surface must be able to withstand loads of traffic, exposure to acids or chemical splashes, and other associated… Continue reading Industrial Floor Painting

Learn More

Industrial Spray Painting & Coating Contractors NJ

Protective coatings are applied on to surfaces/substrates and act as a barrier to inhibit or prevent corrosion. Each Coating is converted into a solid protective, decorative, or functional

Learn More

QA/QC & Third Party Coating Inspection Services NJ

QA/QC Inspection Services With Certified NACE CIP Level 3 Coatings Inspector on staff, Reliable Coatings ensures the highest standards of quality of their work and also offers

Learn More

Industrial & Secondary Concrete And Containment Repair Services NJ

Protect facility equipment and prevent chemical spills to safeguard the environment by using our repair service to restore and protect secondary containment areas. Thes

Learn More

Industrial Surface Preparation & Cleaning Services NJ

Surface Preparation is the method or combination of methods used to clean a surface of a substrate, remove loose and weak materials and contaminants from the surface, repair the surface, and roughen the surface to promote adhesion of a protective coating or lining system.

Learn More

Commercial Pool Painting Service in New Jersey

Expert Solutions for Pool Surface Coatings Maintaining the aesthetic appeal and hygiene of your swimming pool requires ongoing care. In addition to regular water chemistry checks, it’s vital for pool owners and managers to pay attention to the paint coating, as it plays a crucial role in the pool’s durability. Applying a new coat of… Continue reading Commercial Pool Painting Service in New Jersey

Learn More

Thermal spray metalizing | thermal coating & suppliers in NJ

Looking for a protective coatings that can last you up to 50 years? Metalizing or Thermal Spraying might be the solution. Enquire for More Details

Learn More

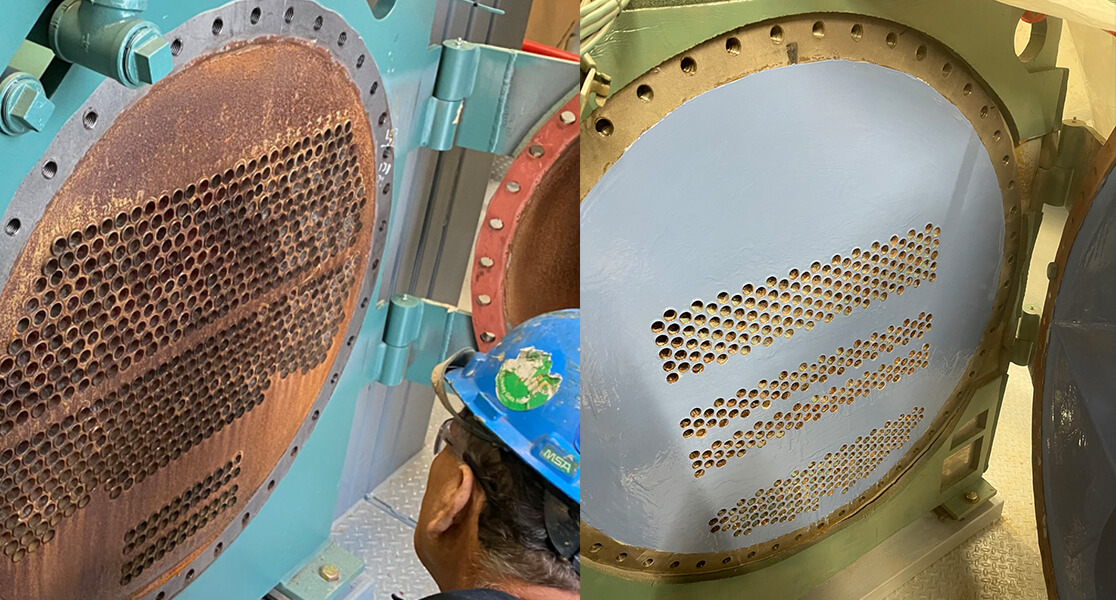

Heat Exchanger & HVAC Chiller Tube Sheet Repair

Heat Exchanger & HVAC Chiller Tube Sheet Repair Fall maintenance may necessitate the chiller tube sheets repairs. Have you realized that your tube sheet has been harmed by galvanic corrosion? So, Take corrective action now rather than face the risk of potential leaks! Corrosion is primarily visible in the form of discoloration, staining, scale, and… Continue reading Heat Exchanger & HVAC Chiller Tube Sheet Repair

Learn More

Sandblasting

What Is Industrial Sandblasting — and Why It Matters Industrial sandblastingis the process of using high-pressure abrasive materials to clean, strip, or prepare a surface — typically metal or concrete — by removing rust, mill scale, paint, and other contaminants. It’s one of the most critical steps in protecting and extending the life of valuable… Continue reading Sandblasting

Learn MoreClient Reviews

Due to the quality & timeliness of their work, as well as highly professional communication and response time, NJ Reliable Coatings has established themselves as a trusted local partner of ours for work involving surface preparation, coatings, lining, and abrasive blasting. Dan and his team are committed to doing things the right way and ensuring the success of their customers. If you are in need of a no hassle, no stress contractor to get the job done, look no further than NJRC.

Ian May Regional Manager- Sponge Jet Inc

Great company to work with! Always looking into new technologies to add value to their clients assets and consistently staying on top of timelines and finishing work to the specification. Would recommend NJ Reliable Coatings for all your coating projects.

Armorica Sales Inc

Due to the quality & timeliness of their work, as well as highly professional communication and response time, NJ Reliable Coatings has established themselves as a trusted local partner of ours for work involving surface preparation, coatings, lining, and abrasive blasting. Dan and his team are committed to doing things the right way and ensuring the success of their customers. If you are in need of a no hassle, no stress contractor to get the job done, look no further than NJRC.

Ian May Regional Manager- Sponge Jet Inc

Great company to work with! Always looking into new technologies to add value to their clients assets and consistently staying on top of timelines and finishing work to the specification. Would recommend NJ Reliable Coatings for all your coating projects.

Armorica Sales Inc

Blog Posts

November 26, 2025

Signs You Need an Industrial Painting Contractor: How to Choose the Right One

Keeping your industrial facility in good condition is vital for its longevity and safety. One of the most overlooked things in the context of maintenance is interior paint, which plays a very important role in the structures, equipment, protection of...

Read More

May 12, 2025

What is the Role of Sandblasting Contractors in New Jersey

Commercial sandblasting, also known as abrasive blasting, is an essential surface preparation procedure for restoration projects. The high-pressure sandblasting machines removes rust with old coatings, grime, and other forms of dirt using abrasive materials. Sandblasting Servicesare extensively used to prepare...

Read More

May 6, 2025

Things to Know About Industrial Sandblasting and Painting

If you’ve been researching how to clean, restore, or prepare metal or concrete surfaces in an industrial setting, chances are you’ve come across the terms sandblasting and industrial painting more than once. “These two processes often go hand-in-hand”. They play...

Read More